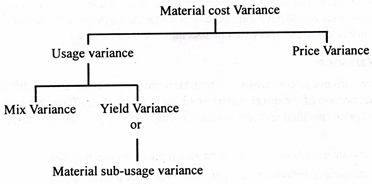

Material cost variance is the difference between the actual cost of direct material used and standard cost of direct materials specified for the output achieved. This variance results from differences between quantities consumed and quantities of materials allowed for production and from differences between prices paid and prices predetermined.

This can be computed by using the following formula:

Material cost variance = (AQ X AP) – (SQ X SP)

Where AQ = Actual quantity

AP = Actual price

SQ = Standard quantity for the actual output

SP = Standard price

Material Usage Variance:

The material quantity or usage variance results when actual quantities of raw materials used in production differ from standard quantities that should have been used to produce the output achieved. It is that portion of the direct materials cost variance which is due to the difference between the actual quantity used and standard quantity specified.

As a formula, this variance is shown as:

Materials quantity variance = (Actual Quantity – Standard Quantity) x Standard Price

A material usage variance is favourable when the total actual quantity of direct materials used is less than the total standard quantity allowed for the actual output.

(a) Material Mix Variance:

The materials usage or quantity variance can be separated into mix variance and yield variance.

For certain products and processing operations, material mix is an important operating variable, specific grades of materials and quantity are determined before production begins. A mix variance will result when materials are not actually placed into production in the same ratio as the standard formula. For instance, if a product is produced by adding 100 kg of raw material A and 200 kg of raw material B, the standard material mix ratio is 1: 2.

Actual raw materials used must be in this 1: 2 ratio, otherwise a materials mix variance will be found. Material mix variance is usually found in industries, such as textiles, rubber and chemicals, etc. A mix variance may arise because of attempts to achieve cost savings, effective resources utilisation and when the needed raw materials quantities may not be available at the required time.

Materials mix variance is that portion of the materials quantity variance which is due to the difference between the actual composition of a mixture and the standard mixture.

It can be computed by using the following formula:

Material mix variance = (Standard cost of actual quantity of the actual mixture – Standard cost of actual quantity of the standard mixture)

Or

Materials mix variance = (Actual mix – Revised standard mix of actual input) x Standard price

(b) Materials Yield Variance:

Materials yield variance explains the remaining portion of the total materials quantity variance. It is that portion of materials usage variance which is due to the difference between the actual yield obtained and standard yield specified (in terms of actual inputs). In other words, yield variance occurs when the output of the final product does not correspond with the output that could have been obtained by using the actual inputs. In some industries like sugar, chemicals, steel, etc. actual yield may differ from expected yield based on actual input resulting into yield variance.

The total of materials mix variance and materials yield variance equals materials quantity or usage variance. When there is no materials mix variance, the materials yield variance equals the total materials quantity variance. Accordingly, mix and yield variances explain distinct parts of the total materials usage variance and are additive.

The formula for computing yield variance is as follows:

Yield Variance = (Actual yield – Standard Yield specified) x Standard cost per unit

Materials Price Variance:

A materials price variance occurs when raw materials are purchased at a price different from standard price. It is that portion of the direct materials which is due to the difference between actual price paid and standard price specified and cost variance multiplied by the actual quantity. Expressed as a formula,

Materials price variance = (Actual price – Standard price) x Actual quantity

Materials price variance is un-favourable when the actual price paid exceeds the predetermined standard price. It is advisable that materials price variance should be calculated for materials purchased rather than materials used. Purchase of materials is an earlier event than the use of materials.

Therefore, a variance based on quantity purchased is basically an earlier report than a variance based on quantity actually used. This is quite beneficial from the viewpoint of performance measurement and corrective action. An early report will help the management in measuring the performance so that poor performance can be corrected or good performance can be expanded at an early date.

Recognizing material price variances at the time of purchase lets the firm carry all units of the same materials at one price—the standard cost of the material, even if the firm did not purchase all units of the materials at the same price. Using one price for the same materials facilities management control and simplifies accounting work.

If a direct materials price variance is not recorded until the materials are issued to production, the direct materials are carried on the books at their actual purchase prices. Deviations of actual purchase prices from the standard price may not be known until the direct materials are issued to production.

2 thoughts on “Material Variance”