Value chain analysis is a framework developed by Michael Porter that divides the company into primary and secondary activities related to delivering a product or service. The primary activities include inbound logistics, operations, sales and marketing, and outbound logistics. The secondary activities are supporting activities and include the firm infrastructure, human resources, information technology, and procurement.

The components of the value chain

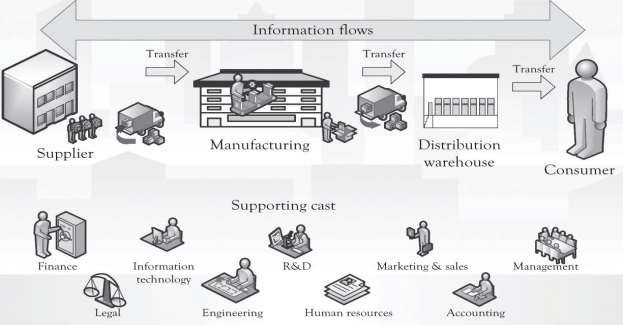

A closely related concept is the supply chain. A supply chain is defined as the connected activities related to the creation of a product or service up through the delivery of the product to the customer. It includes upstream suppliers as well as downstream activities such as wholesalers and distribution warehouses. Figure illustrates the supply chain.

In general, the terms value chain and supply chain can be used interchangeably; although the value chain is rooted in the strategic planning literature, the supply chain is linked to the work in the operations management area. The key concept is that products and services have to be created and eventually delivered to consumers and the in-between activities can be referred to as the supply chain or the value chain.

The supply chain is an important visual tool because it can be used to understand where to look for processes that can be reengineered. That is, improvements can be made in connecting, coordinating, and controlling activities across linkages. It can also be used to determine what kind of information should be gathered to improve communications throughout the value chain and where value chain performance could be improved. For example, the firm can investigate where information technology can be marshaled to support the supply chain activity and where technology can be used to automate tasks. The goal, of course, is to reduce transaction costs up and down the supply chain. Transaction costs refer to the effort that goes into choosing, organizing, negotiating, and entering into agreements for products and services. Transaction costs come in a variety of flavors and there is significant overlap among the various costs.

- Search costs: In general, these costs are related to gathering information on a product or service, including the costs associated with locating a product and offering a product for sale.

- Discovery costs: These costs are involved in locating an acceptable price for a product.

- Decision costs: These costs are associated with making a decision on what product to purchase. These include personal cognitive effort and organizational decision processes related to selecting a product or service.

- Negotiation costs: These costs are related to agreeing to the terms of a contract including the price, what will be delivered, how much, and when.

- Acquisition costs: These costs are involved in transporting, receiving, infrastructure development, and managing the product in inventory.

- Enforcement costs: These are the costs that the parties in the contract incur in order to enforce the terms of the contract.

- Settlement costs: These are the costs related to paying and getting paid for a product or service.

- Social costs: These include costs that are not necessarily picked up by the buyers and the sellers. Examples include pollution costs, health costs, privacy costs, and bankruptcy costs.

Supply Chain Analysis

Supply chain analysis is the process of evaluating every stage of a supply chain starting from the time the business acquires raw materials or supplies from its suppliers to the delivery of final products to the customers. The purpose of the analysis is to determine which part of the supply chain can be improved or shortened to deliver the product more quickly and efficiently to the customers. The philosophy behind supply chain analysis is that the more flexible a business can be, the faster its growth rate will be.

Supply chain analysis helps businesses identify the suppliers and/or processes that can be bypassed, reduce inventories, schedule events and programs, and improve forecasts. This increases efficiency, reduces costs and minimizes risks. It helps businesses optimize their processes to remove redundancies in the supply chain while helping create new value-added processes.

Conducting a supply chain analysis involves the following steps:

- Mapping the Supply Chain

This involves identifying all the organizations, people, activities, information and resources involved in the supply chain and creating a flowchart to obtain an overview of the chain, the flow of raw materials and product, the position and function of chain actors and the type of interaction between the actors.

- Developing Economic Accounts Corresponding to Each Actor Involved in the Supply Chain

This involves quantifying the activities of each actor and contribution to the flow of materials both in physical and monetary terms. It helps the analyst assess the importance of the actor in the chain and to point out where the weaknesses lie and how they can be rectified.

To start a complete supply chain analysis, you need to collect data pertaining to every actor and every stage of the supply chain. This requires a lot of research and hard work. Most small and midsize businesses rely on manual methods of data collection and the use of spreadsheets, such as Microsoft Excel, for analysis.

A faster and easier way to conduct the analysis is to use a software program to automate the process. Such a program can extract information from all the different sources into one console removing the need for tedious and time consuming manual data collection. You can analyze shipping schedules, improve transportation and inventory planning, increase transportation management efficiency and track just-in-time delivery metrics.

Some top of the line software programs for supply chain analysis have advanced and useful features like data blending and cross-data source triggers, built-in geocoding, built-in calculation support, connectivity to external web services and support for WMS mapping services. The programs require considerable investment, but the saving on time, efficiency and accuracy amply compensates for that.

One thought on “Value and Supply Chain Analysis”