Integrated Logistics Management can be defined as the process of anticipating customer needs and wants, acquiring the capital, materials, people, technologies and information necessary to meet those needs, optimizing the goods or service, producing a network to fulfill customer requests and utilizing the network to fulfill customer requirements in a timely manner.

Integrated logistics is thus concerned with bringing connectivity in various logistical activities and performing the logistics function as one single chain rather than many isolated functions. This helps in reducing the operational efforts and costs and performance wise it leads to better customer service and higher revenues for the company.

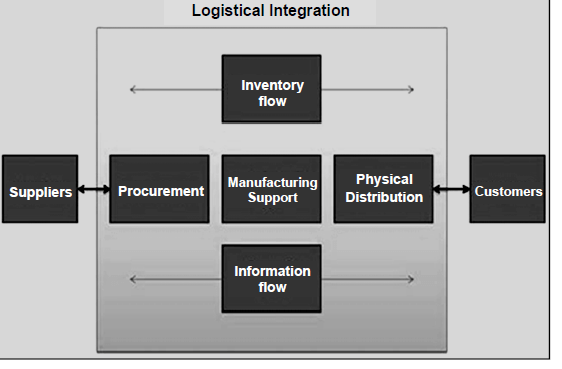

Flows in Integrated Logistics:

As logistical activities need to be integrated in one single chain, efforts are taken to unite two main categories of flows of logistics viz. Information Flow and Inventory Flow.

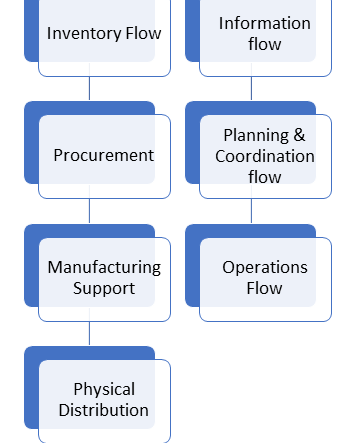

(a) Inventory flow: It is concerned with how the raw materials are purchased from suppliers, processed and finally delivered to the customer. It represents the Logistical performance cycle encompassing inbound, in process and outbound logistics. Inventory Flow thus, covers procurement, manufacturing support and physical distribution.

(i) Procurement: Procurement is concerned with getting raw materials from the vendor and make available for further processing as and when required. It aims at carrying out logistics elements related to procurement of materials at lower price. It involves all preproduction logistical activities.

(ii) Manufacturing Support: Manufacturing support is an interface between the procurement and physical distribution. The activities under this flow aims at providing basic support in manufacturing. It includes material handling, managing work in progress inventory and transferring finished goods to warehouse.

(iii) Physical Distribution: includes all those elements of logistics which are necessary to distribute the goods from the manufacturer’s warehouse to the customer’s warehouse. It ensures that goods are delivered to the customer according to his order following 7Rs principle of Customer Service.

(b) Information Flow: Information flow aims at developing coordination among various ends and performs the logistical functions in the righteous manner enabling logistical competency. It includes Planning and Coordination Flow and Operations Flow:

(i) Planning and Coordination Flow: Planning and Coordination is the base of logistics chain that provides an integrated method of working by the participants of value chain. Requirements are consolidated and finally a plan is made to carry out logistical operations in an integrated way to satisfy all the value chain participants.

(ii) Operations Flow: It is concerned with directing operations to receive the order, process it, carrying our functions like warehousing, material handling and transportation and finally distributing the goods according to an order.

Barriers to Integrated Logistics:

Integration of Logistics is not an easy task. There are certain barriers in the whole process. These barriers could be listed as follows:

(a) Organization Structure: Integration of logistical function requires on the part of manager to look beyond the aspects of authority and hierarchy in the organization structure. Traditional perspectives by managers need to be ignored and new integrated approach is essential.

(b) Measurement Systems: Managers generally have a thinking to look their functions individually but integrated logistics require from the part of managers to see their functions as a part of business system. A new measurement system with holistic approach is needed.

(c) Inventory Ownership: Integrated logistics aims at managing inventory in altogether a different way. Whereas, traditionally inventories are managed to maintain sufficient supply and remain in a comfort zone. Integrated logistics aims at modern inventory management techniques like JIT wherein inventory carrying costs are reduced considerably.

(d) Information Technology: Information technology that is required to meet the requirements of integrated logistics is not available easily as it requires cross functional approach. Moreover such technologies are really very expensive.

(e) Knowledge: Competency among the employees involved in integrated logistics is essential Failure to have such competency may not serve the purpose.